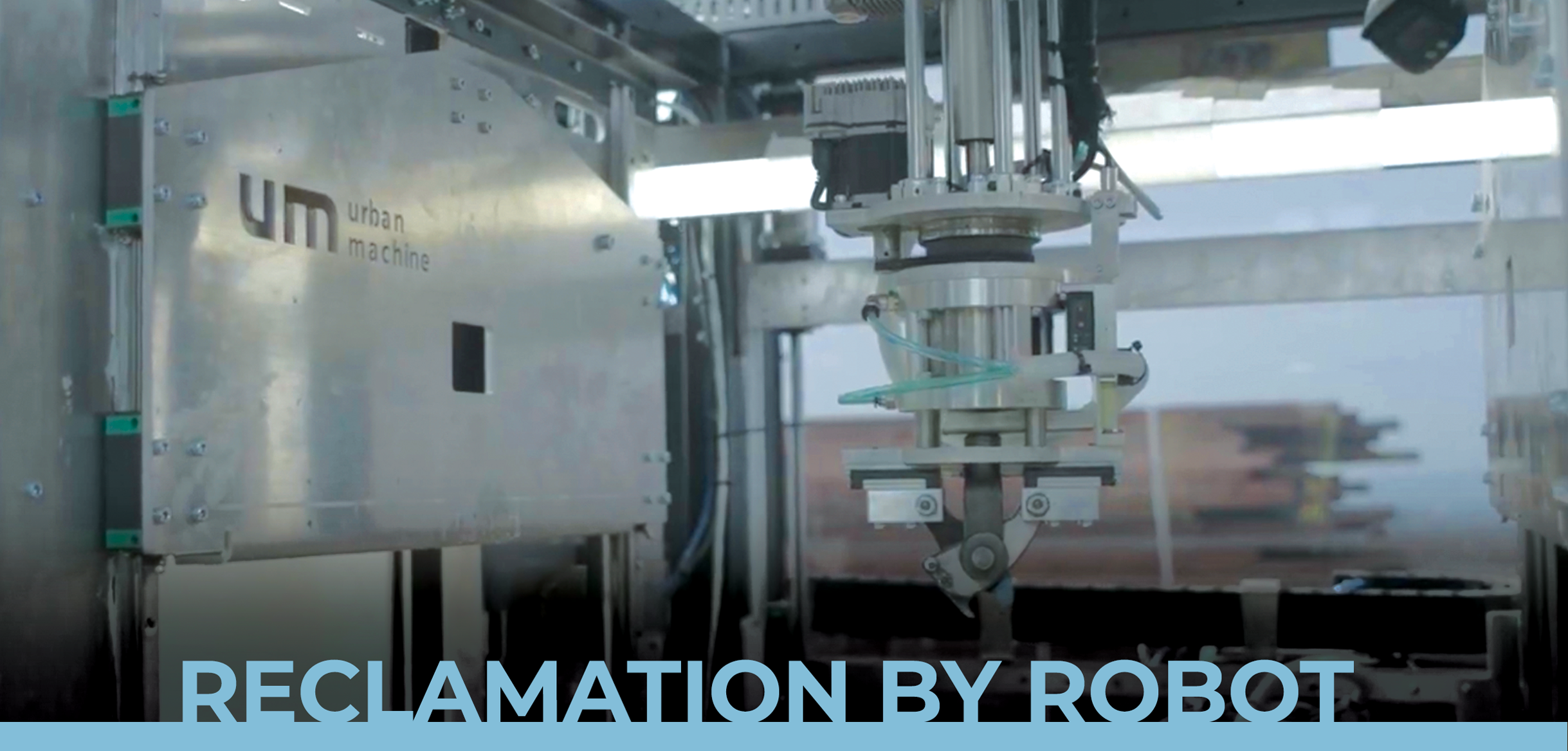

Robotics and AI are arriving on-site—to salvage and revive lumber that’s beenleft for dead.

“We’re gonna x-ray it, we’re gonna scan it, make sure it’s structurally intact and still rigid,” says Urban Machine CEO Eric Law. He’s talking about a salvaged glulam beam, and how his company combines robotics and artificial intelligence to give it new life. “The last building it came out of, it wasn’t falling down or failing, so it should be good to go in another building.”

Wood waste in the United States weighs an estimated 37 million tons, so reclaiming it would seem to make sense. The problem, however, is all the nails, staples and screws trapped inside that wood. That’s where Urban Machine’s eighty-foot mobile unit enters the picture.

Parked at a construction or demolition site, The Machine uses computer imaging, depth sensory cameras, and AI algorithms to provide a 3D point cloud of every piece of dimensional lumber they feed it. Next, a series of robotic arms outfitted with pincers and extractors pry out or reverse-turn every last nail, staple, and screw. Finally, after passing through a metal detector to audit the process, the piece is brushed, cleaned, and ready to be reused—sometimes on the very same site.

Because the softwood is now aged, it comes back harder, stronger, and richer in color in this new iteration, making it an appealing option for furniture makers, too. “Here’s a high value product, and it’s got a story behind it,” Law says in the podcast linked below. “’This bookcase was made here and the wood came from this particular building down the street.’”

Urban Machine has an ambitious agenda for all that wasted wood, aiming over time to reclaim fully half of it—18.5 million tons. They plan to have twelve Machines fully operable and available to rent by next year.

Close The Deal: “How To Reclaim Lumber at Scale Using AI”

Trellis: “These 2 startups preview the future of AI in the circular economy”

Video: “Urban Machine’s Roots”